Punches, shaping life

Punches for ceramic molds

precision in detail

Punches represent much more than just a mold component: they are the tool that shapes and characterizes each ceramic piece. Thanks to their precision, strength and specialized design, they allow obtaining surfaces and finishes of great quality. At Cortes, we transform innovation and experience into punches capable of responding to today's industry challenges. Our goal is to support our clients with versatile solutions that enhance creativity, strengthen competitiveness, and elevate the value of ceramics in each project.

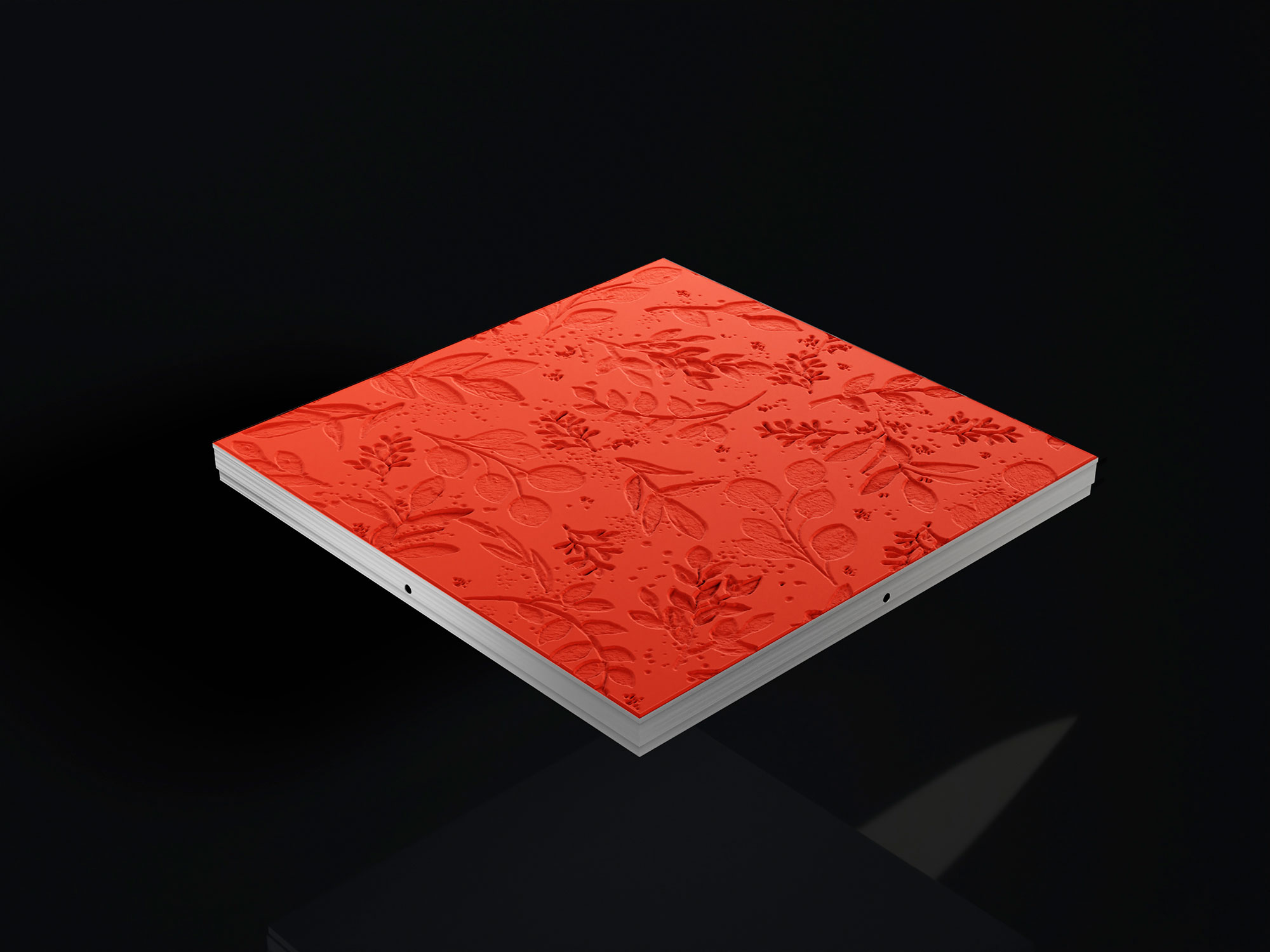

Punches

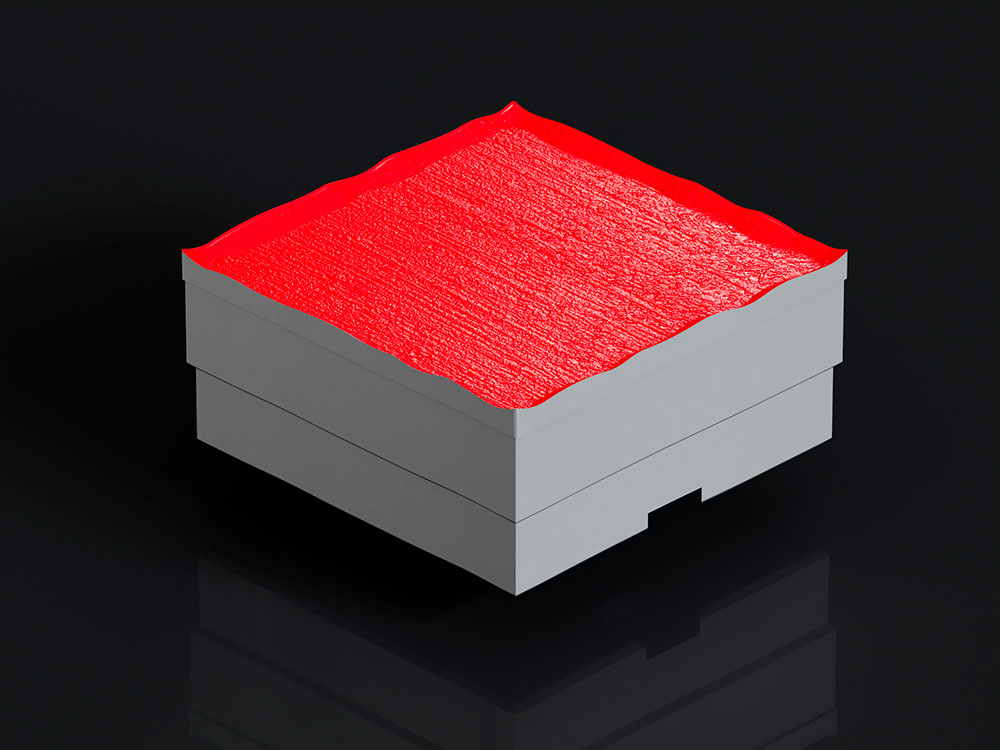

relieves / structured

These punches are used to manufacture ceramic relief pieces, without restrictions on height or complexity of geometry. At Talleres Cortés, our design department can transform any image, idea, or concept into a functional punch, making possible the production of ceramic pieces with their own identity.

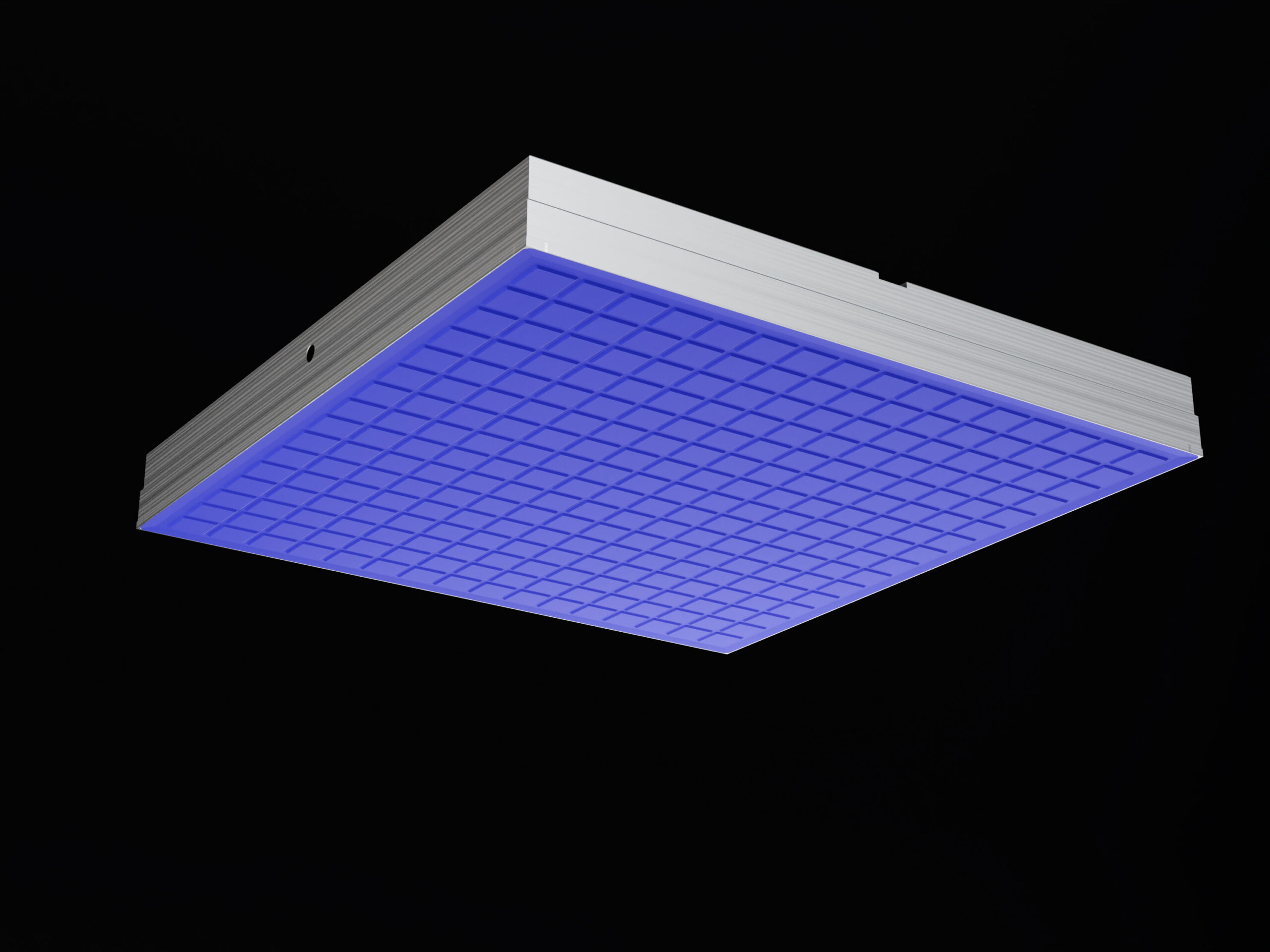

Punches

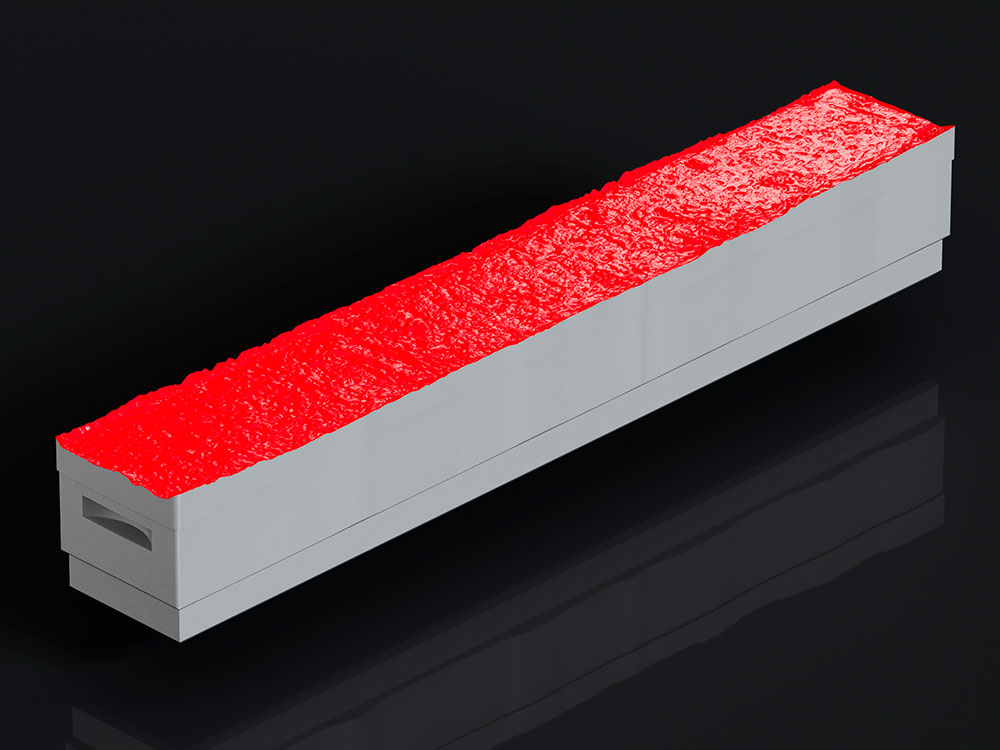

Macizos

Cara Mala

Rib / Moratura

This type of punches is used to form the non-visible face of the tile, that is, the surface that remains in contact with the floor or wall after installation. It generally features a grid or other texture designed to improve adhesion with cement or fastening materials. In short, these punches are responsible for shaping the rear or reverse side of the ceramic piece.

Land saving

Compensation of pronounced reliefs or high-reliefs

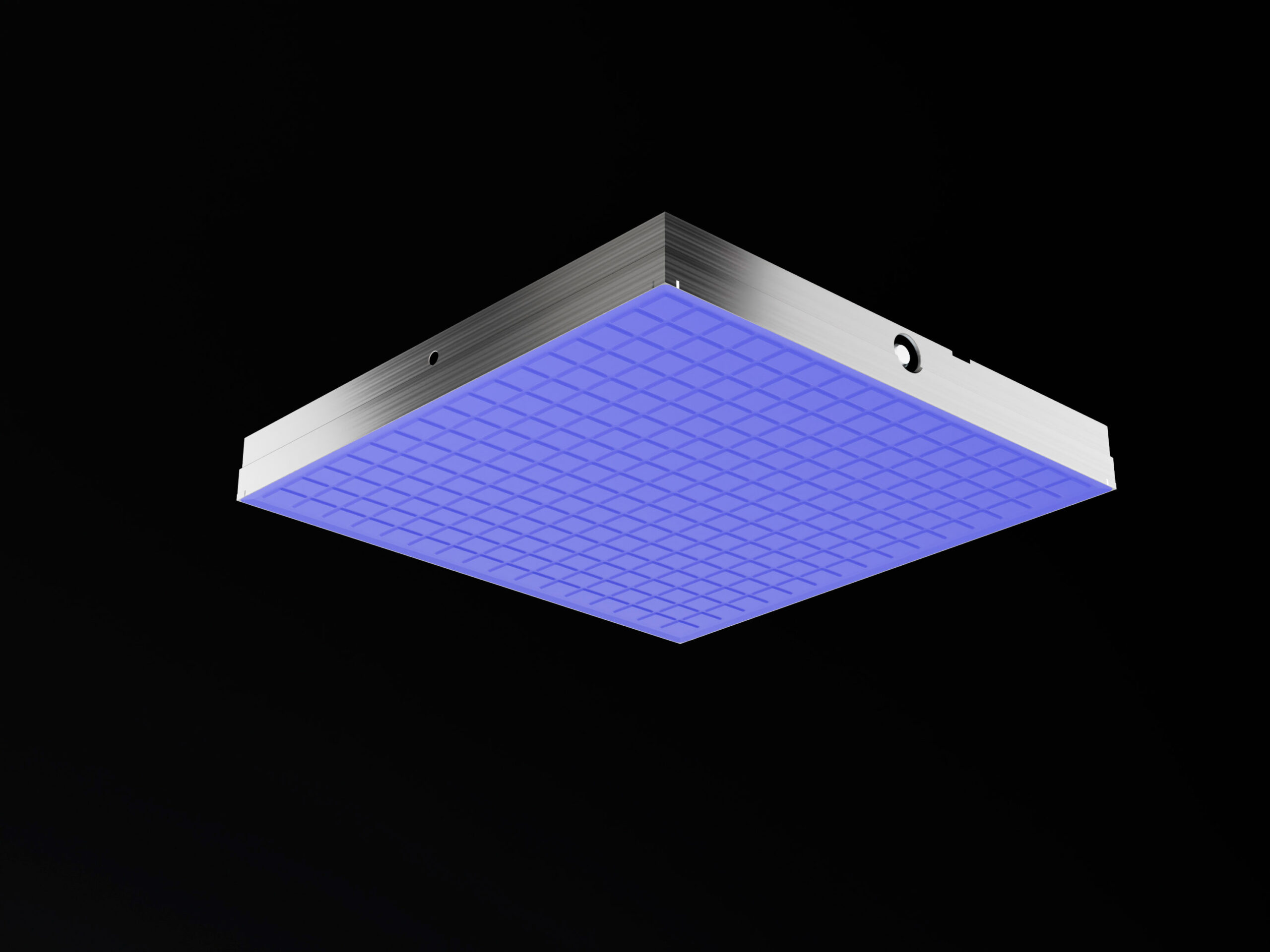

Punches

Isostatic

Isostatic punches are distinguished by incorporating an internal oil circuit. When the press applies pressure on the ceramic mixture, the oil moves inside the punch, allowing the force to distribute evenly. Thanks to this homogeneous pressure, the molded piece achieves a more consistent and higher-quality apparent density.

Longer tool life

Pressed tile higher quality

Homogeneity during the pressing process between the different cavities

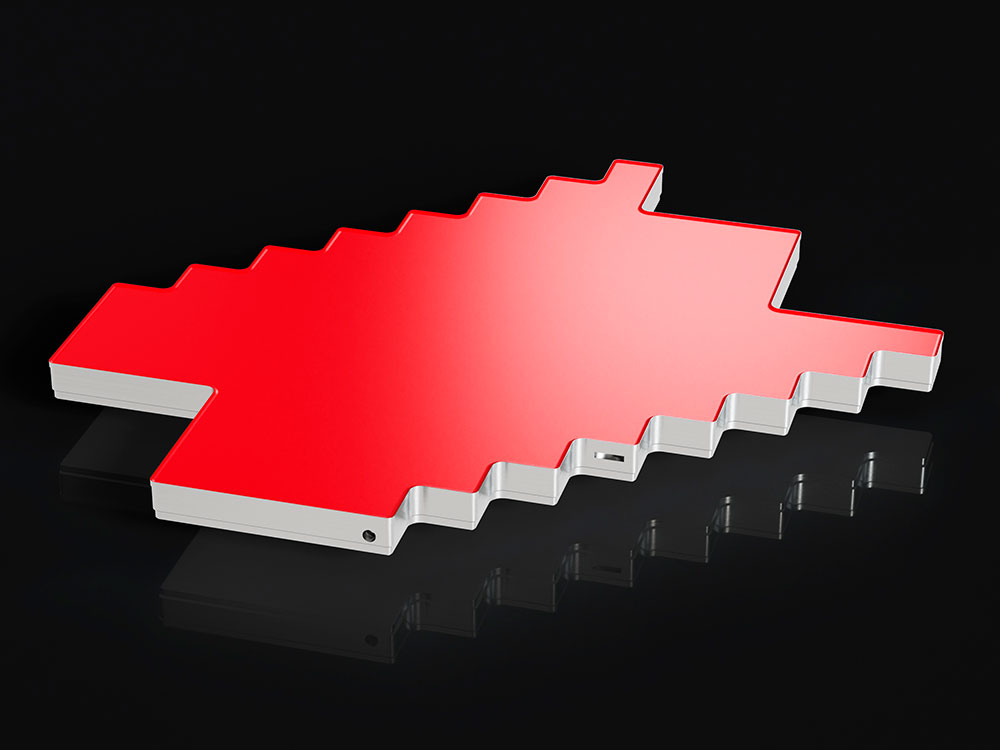

Punches

Irregular outline

We manufacture punches for a wide variety of formats, geometries, and working conditions, adapting to the specific needs of each production line. Each model is designed to ensure dimensional stability, high wear resistance, and optimal integration with the rest of the pressing tooling.

Advanced